The challenge facing our client in the tooling and machinery sector is how to optimize the part’s performance and add new features, while cutting manufacturing costs.

This tooling and machinery sector part is designed to be mounted on plows. It was originally a welded assembly, made from a sand cast part and a machined part. By transitioning to investment casting, our client was able to reduce the number of manufacturing operations.

Substantial manufacturing cost savings were obtained thanks to the monobloc casting process. The part’s overall performance was improved and new features could be added.

The Nowak foundry solutions

So how does the new monobloc foundry cast part differ from the original welded part?

Investment casting eliminates all the welding operations and produces a single foundry cast part.

The original welded assembly part required milling a separate block, sandcasting the toothed part, then welding the two parts together. The part then had to be stamp-marked.

Other foundry cast tooling and machinery parts benefited from the change-over to this manufacturing process.

What features have been integrated in the monobloc foundry cast part?

The tapping on the original welded assembly part was replaced by a nut housing. The locking system was simplified.

The stamp marking stage was replaced by a marking cast directly in the part.

The Nowak foundry can also provide the final protection stage with a zinc-coating surface treatment or by painting.

How does this improve the ratchet yoke’s efficiency?

By eliminating the welding stage, it was possible to change the steel for a special tooling and machinery foundry-specific steel, with improved mechanical properties.

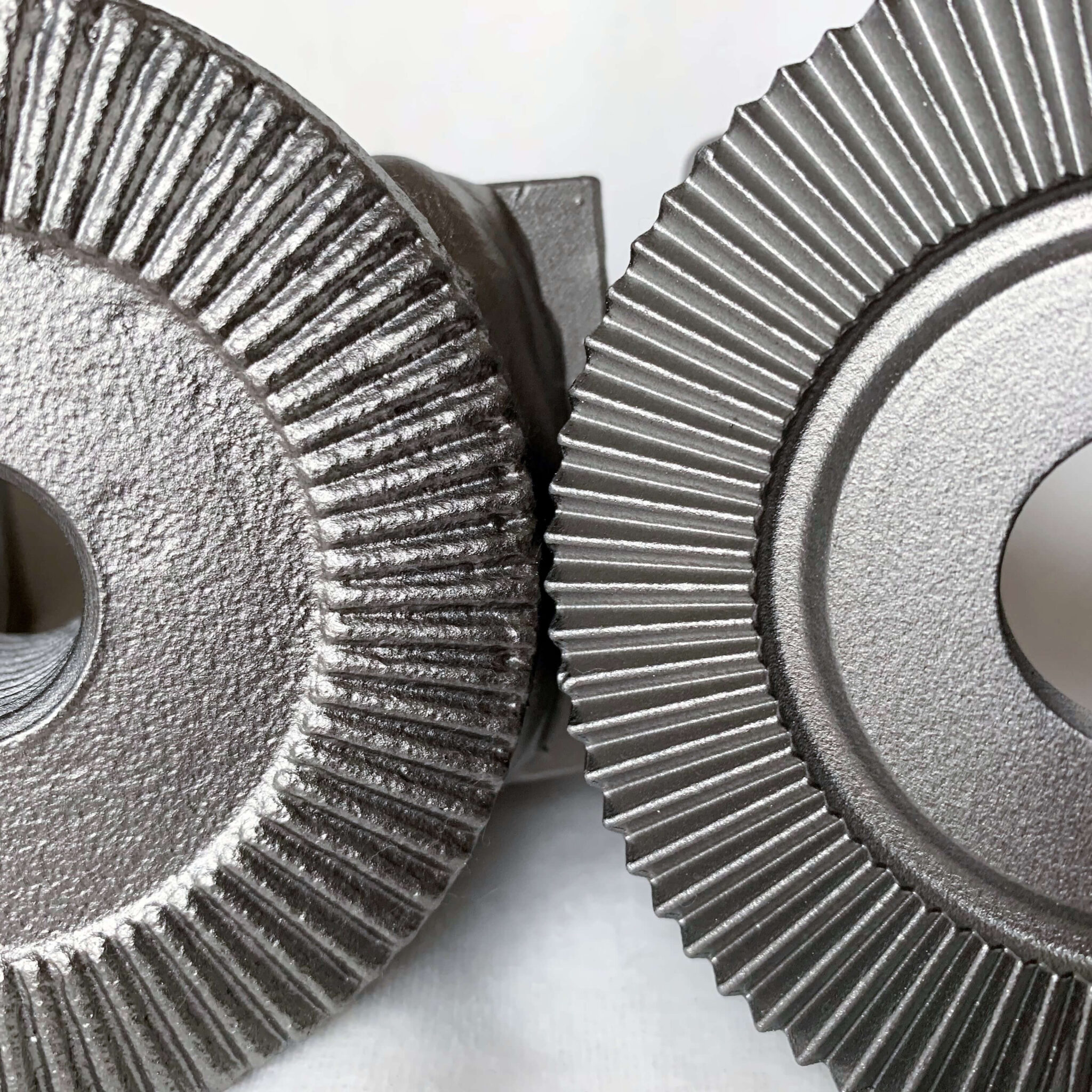

The Nowak investment casting process enables high precision tooth casting on the monobloc part, which therefore increases the gear’s energy performance.

The part is also 20% lighter, which reduces strain on the equipment without reducing shock and wear resistance.

Design flexibility and dimensional accuracy:

Find out more about the advantages of our investment casting process.

Metallurgical engineering advice, rapid prototyping:

Just two of the support services that Nowak precision investment casting can provide.